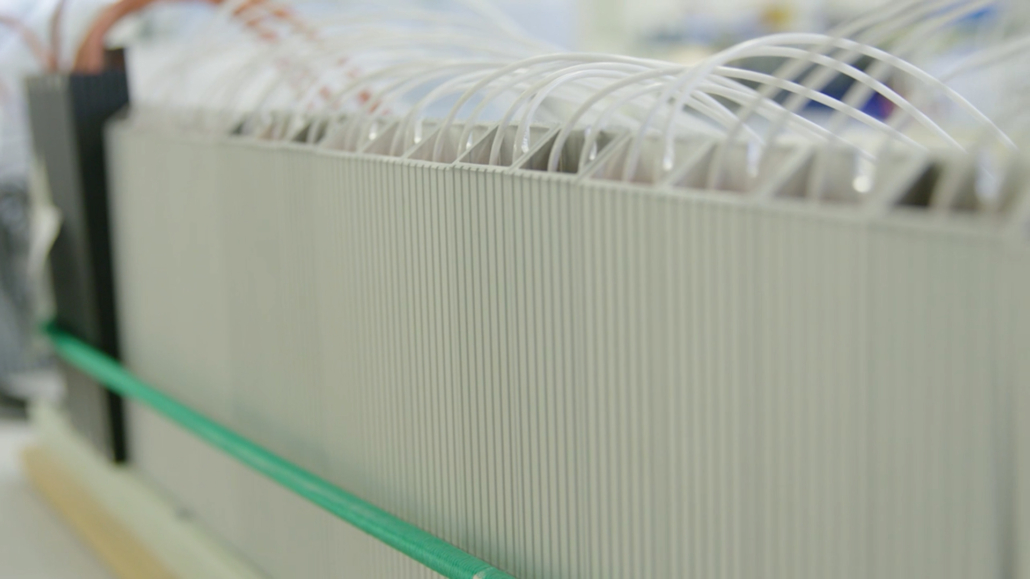

The REOhm braking resistor can absorb and store energy for a short time due to a special type of winding. The energy leads to a thermal change, a heating of the braking resistor. Thanks to appropriate filling and compression, the thermal energy can be quickly transported to the surface during the pauses and released to the environment through contact with the cooling air. A heat sink increases the contact surface with the air by means of grooves and bars and accelerates the removal of heat. Even better cooling conduction is achieved by special heat-conducting fluids in series with the REO liquid cooling system.

Due to the rapid cooling of the winding body, whether by air or liquid, pulses of various intensities or durations can be continuously absorbed and do not lead to destruction of the component. The REOhm braking resistors of the standard series are designed for a duty cycle of 5% -100% – smaller duty cycles are also possible on request.